Services

Tiers Repairs done quickly when you need it.

Standard

7 - 10 Business Days

Expedite

3 - 5 Business Days

Rush

Immediate Evaluation, 1 Business Day

Services Available

Rewinding

- Fractional to Large HP winding

- Largest rewind to date: 1000Hp

- Also wind brake and magnet coils

- Class H Insulation System

- Dedicated rewind department

- Winding redesigning software

- Large stock of magnet wire

- Hermetic (oil) rated materials available

- Dip and Bake process

- Express/Rush winding available

- Over 40 years winding experience

- Form and Random wound coils

- Temperature controlled burn-out oven

- Multiple bake ovens

- Capable of rewinding servo motors

- Wide variety of winding heads

- Inverter rated wire

- Multiple winding machines

- Core-loss and Surge testing

- Epoxy for wet / harsh conditions

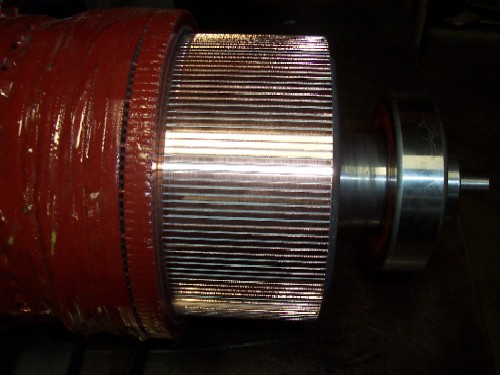

Machining

Before

After

Welding

General Welding

- Wire, Spray, AC&DC TIG Welding

- ALL welding done in house

- Aluminum, Cast, or Stainless

- Suitable for food grade applications

- Turn table used to avoid warpage

Spray Welding

- Low temp thermal spray process

- Safe for servo magnet material

- Hardness of RC 30-70 per application

- Mirror finishes for seal surfaces

- Faster process to lower machining costs

Encapsulation

Balancing / Vibration

Additional Service Info

Free Evaluation

The full inspection and evaluation of your motor is free upon request. We will first provide you with a detailed quote letting you see what the problem was, and what it will cost to fix it, before beginning the repair.

Time & Material Billing

We do not believe in preset repair pricing. Our time and material billing system ensures both fair competitive pricing and a high quality-to-value ratio repair.

24 Hour Emergency Service

Exactly what it sounds like. You have a problem, call us. We will do everything possible to get you up and running, no matter what time of the day, or day of the week.

Crane Service

We work closely with other businesses in the area to provide a value priced crane service for motors too large to move by hand.

Expert Cross-Reference

Don't have time to wait for an OEM replacement? Or can't find a replacement? We can cross reference your motor to several other manufacturer's to get you the product you need.

Custom Modifications

Can't find a motor to fit your application? Are replacements no longer available? We modify new motors IN HOUSE to meet your specs and size requirements.

Free Pick-Up / Delivery

We regularly pick up and deliver for many of our local customers. Not sure if you qualify? Give us a call and find out. 920-982-4055